irBoard Player

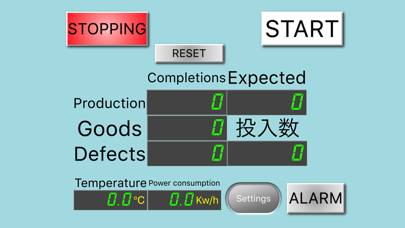

Using irBoard Player, you can conveniently monitor the status and operation of FA equipment and IoT devices through an iPad or any other iOS device.

The control device known as a PLC (Programmable Logic Controller) has communication protocols. irBoard Player communicates with PLCs via its protocol.

Additionally, it has the capability to communicate effectively with IoT devices, specifically the ESP32 device at present.

For creating project data, you need to use the paid version of irBoard or purchase an In-app-purcahse item of irBoard Lite.

FEATURE:

- You can conveniently monitor the status and operation of FA equipment and IoT devices.

- Although the FA equipment has fixed touch panels installed, the irBoard Player on iOS devices offers superior portability.

- It is possible to remotely check the status of a device in PLCs.

- To ensure safety, manipulating connected PLC devices is only allowed on a single iOS device.

- By switching projects, you can easily connect to multiple FA machines using just one iOS device.

- irBoard Player supports the following PLCs via Ethernet connection: MITSUBISHI Electric, KEYENCE, OMRON, and YOKOGAWA Electric, and support Modbus/TCP.

- It can also connect to an open-source PLC LadderDrive running on Raspberry Pi. (https://github.com/ito-soft-design/ladder_drive)

- The irBoard Library for ESP32 library supports ESP32 devices.(https://github.com/ito-soft-design/irboard_esp32)

- The irBoard.NET library supports Windows .NET applications.(https://github.com/ito-soft-design/irboard-dotnet)

- Using the LadderDrive protocol, allows for communication with IoT devices such as ESP32 without any difficulty.

=====================================

--- Notes ---

With irBoard Player, you have the ability to turn devices on and off. If you require the interlocking of PLC-controlled devices, it is necessary to configure this on the PLC. To ensure safety, we suggest setting the status of such devices to read-only.

You can monitor the health status to determine if the connection is stable. If the connection is lost, it’s important to take precautionary measures when operating your PLC.

=====================================